Stainless steel welding outlets play an indispensable role in modern piping systems, providing secure, corrosion-resistant, and efficient branch connections.

Stainless steel welding outlets, commonly known as weld-o-lets, are integral components used for branching pipe connections in various industries. These fittings provide a secure, leak-proof connection between the run pipe and the branch pipe. By ensuring a strong and permanent joint, stainless steel welding outlets support systems that must endure high pressure, temperature fluctuations, and corrosive environments. Their design makes them the preferred choice for industries such as oil and gas, chemical processing, power generation, shipbuilding, and water treatment plants.

Welding outlets are specifically designed to offer a reinforced branch connection. Unlike traditional T-joints or reducing tees, welding outlets are welded directly onto the run pipe, minimizing stress concentration and enhancing structural integrity. This results in better fluid flow and lower turbulence, making them suitable for critical applications where system efficiency and safety are paramount.

Stainless steel welding outlets are manufactured using premium grades of stainless steel, ensuring durability, corrosion resistance, and high performance. Commonly used grades include 304, 304L, 304H, 316, 316L, 316H, 317, 317L, 321, 321H, 347, 347H, 904L, Duplex 2205, Super Duplex 2507, and Alloy 20. Each grade offers unique benefits, such as enhanced pitting resistance, superior weldability, or better performance in highly corrosive environments.

For highly demanding applications, duplex and super duplex stainless steels are preferred due to their combination of strength and resistance to stress corrosion cracking. Grades such as 904L are chosen for their ability to withstand aggressive acids and high-chloride environments. These wide material options allow industries to select welding outlets tailored to their specific operating conditions, ensuring reliability and extended service life.

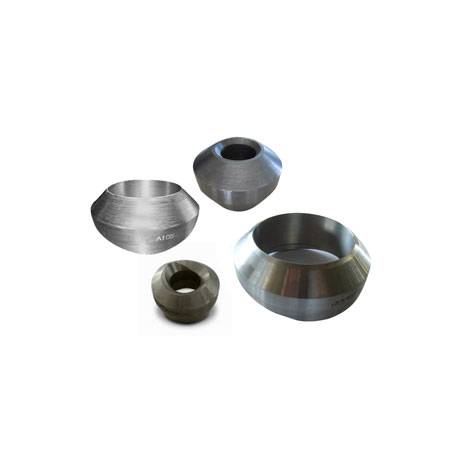

Stainless steel welding outlets are available in various types to meet diverse piping system requirements. The most common include:

These variations ensure that stainless steel welding outlets can cater to a range of piping designs, from standard to highly customized configurations.

Stainless steel welding outlets offer several advantages that make them a preferred choice for critical piping systems:

Stainless steel welding outlets are extensively used across industries that require robust and reliable piping systems. Typical applications include: