Stainless Steel 310 Round Bars remain a preferred choice for industries requiring high-performance materials that can withstand extreme conditions. With their excellent combination of durability, corrosion resistance, and high-temperature strength, these round bars provide long-lasting solutions for a wide variety of applications.

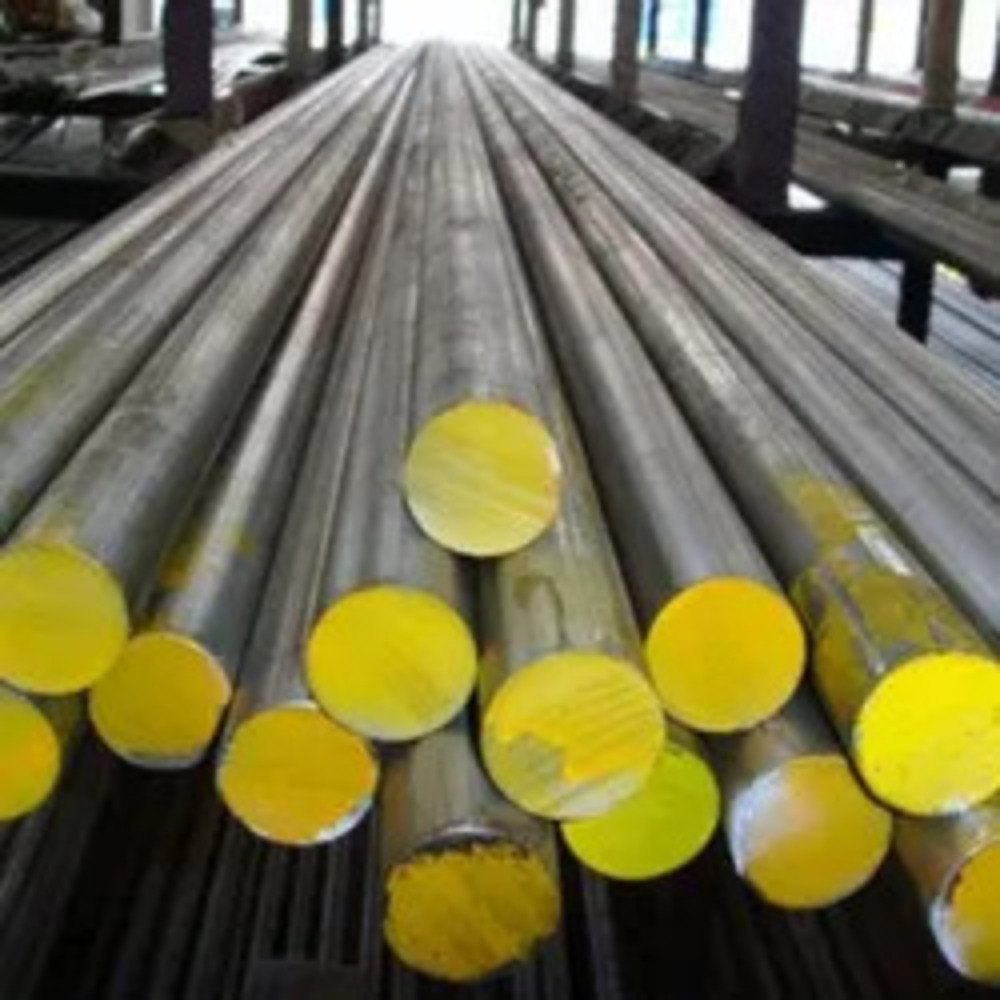

Stainless Steel 310 Round Bars – High-Performance Solution for Extreme Conditions

Stainless Steel 310 Round Bars are one of the most sought-after industrial materials due to their exceptional strength, durability, and resistance to high temperatures and oxidation. These round bars are widely used in various applications, from construction and engineering to chemical processing and power generation. SS 310 Round Bars offer a unique combination of heat resistance, corrosion protection, and superior toughness, making them suitable for demanding environments where conventional stainless steels might fail.

Why Choose Stainless Steel 310 Round Bars?

Stainless Steel 310, an austenitic stainless steel grade, is known for its outstanding performance at elevated temperatures. The round bars made from this grade maintain their mechanical integrity even in highly oxidizing and carburizing atmospheres. 310 Stainless Steel Round Bars are widely preferred for their ability to withstand thermal cycling and maintain structural stability under intense heat.

In industries where reliability and longevity are crucial, SS 310 Bars are a top choice. They are easy to fabricate, weld, and machine, ensuring efficiency and consistency in industrial processes.

Key Features and Benefits

- High Temperature Resistance: With excellent oxidation resistance, Stainless Steel 310 Round Bars can perform continuously at temperatures up to 1150°C.

- Superior Corrosion Resistance: The chromium-nickel composition offers enhanced resistance to corrosion and scaling.

- Excellent Strength and Durability: Retains mechanical properties even under prolonged exposure to high heat.

- Versatile Applications: Ideal for furnace parts, heat exchangers, kilns, and other high-temperature systems.

- Ease of Fabrication: Simple to machine, weld, and form into various components.

Common Sizes and Finishes

Stainless Steel 310 Round Bars are manufactured in a variety of sizes, diameters, and finishes to meet industry standards. Some of the popular finishes include:

- Bright Bars: Smooth surface finish for superior aesthetics and minimal machining needs.

- Black Bars: Hot-rolled bars with a dark surface, ideal for further processing.

- Polished Bars: Highly finished for specialized applications that require excellent surface quality.

- Centreless Ground Bars: Precision ground to close tolerances for critical engineering applications.

Available diameters generally range from 5mm to 500mm, with customized lengths offered upon request.

Applications Across Industries

Due to their unique combination of heat and corrosion resistance, Stainless Steel 310 Round Bars find use in a wide range of industries:

- Petrochemical and Chemical Processing: Used in reactors, piping systems, and heat exchangers.

- Power Generation: Ideal for boiler components and turbine parts operating under high temperatures.

- Construction and Infrastructure: Used in structural frameworks requiring strength and durability.

- Furnace and Kiln Components: Suitable for radiant tubes, burners, and conveyor belts.

- Aerospace and Automotive: Applied in components exposed to extreme heat and oxidizing environments.

- Food Processing and Pharmaceutical Industries: Preferred for their non-reactive and easy-to-clean properties.

Advantages of Choosing SS 310 Round Bars

- Longevity and Reliability: Minimizes maintenance costs due to high durability.

- Excellent Thermal Stability: Withstands rapid changes in temperature without distortion.

- Cost-Effective Solution: Offers long-term value by reducing downtime and replacement frequency.

- Global Standards Compliance: Manufactured as per ASTM, DIN, JIS, and other international specifications.