Stainless Steel Barred Tees are an integral part of modern piggable piping systems, ensuring safe and efficient fluid transportation across critical industries. Available in a wide range of stainless steel grades, sizes, and standards, they provide unmatched durability, corrosion resistance, and reliability.

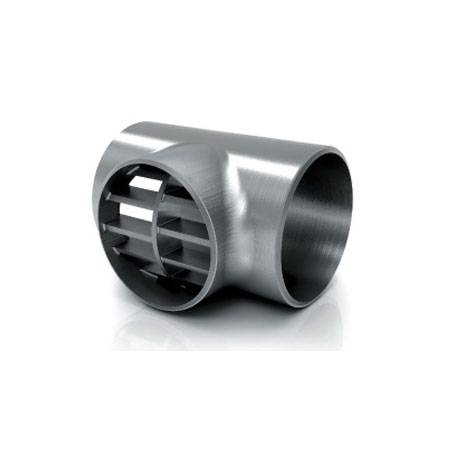

Stainless Steel Barred Tees are specialized fittings designed to control fluid flow in pipeline systems, particularly in pigging operations where cleaning or inspection devices are sent through the pipeline. These tees feature a unique internal structure with welded bars that guide the pig smoothly through the branch connection, preventing it from getting stuck or damaged. Widely used in the oil & gas, petrochemical, and energy sectors, stainless steel barred tees offer exceptional durability, resistance to corrosion, and reliable performance under high-pressure conditions.

A barred tee is a type of tee fitting used in piggable pipeline systems. Unlike a standard tee, it has bars welded inside the branch opening to protect pipeline pigs while allowing fluid flow into the branch. These bars prevent damage to pigs and ensure uninterrupted inspection or cleaning. They are manufactured according to international standards like ASME B16.9, MSS-SP-75, and DIN specifications, ensuring consistent quality and performance.

Stainless steel is the material of choice for barred tees due to its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures and pressures. Whether it’s transporting oil, gas, chemicals, or other aggressive fluids, stainless steel barred tees ensure reliability and long service life.

Stainless steel barred tees are available in a wide range of material grades to meet the demands of different industries:

Austenitic Stainless Steels –

Duplex & Super Duplex Stainless Steels –

Stainless steel barred tees are produced according to global standards, ensuring interchangeability and reliability: