Stainless Steel 32760/50 Sheet Plate Coils are the ultimate choice for industries demanding high performance, durability, and corrosion resistance. With a wide variety of finishes, dimensions, and customization options, they meet the rigorous standards of modern engineering applications. Whether for offshore platforms, chemical processing plants, or architectural features, SS 32760/50 sheets, plates, and coils provide unmatched reliability and value.

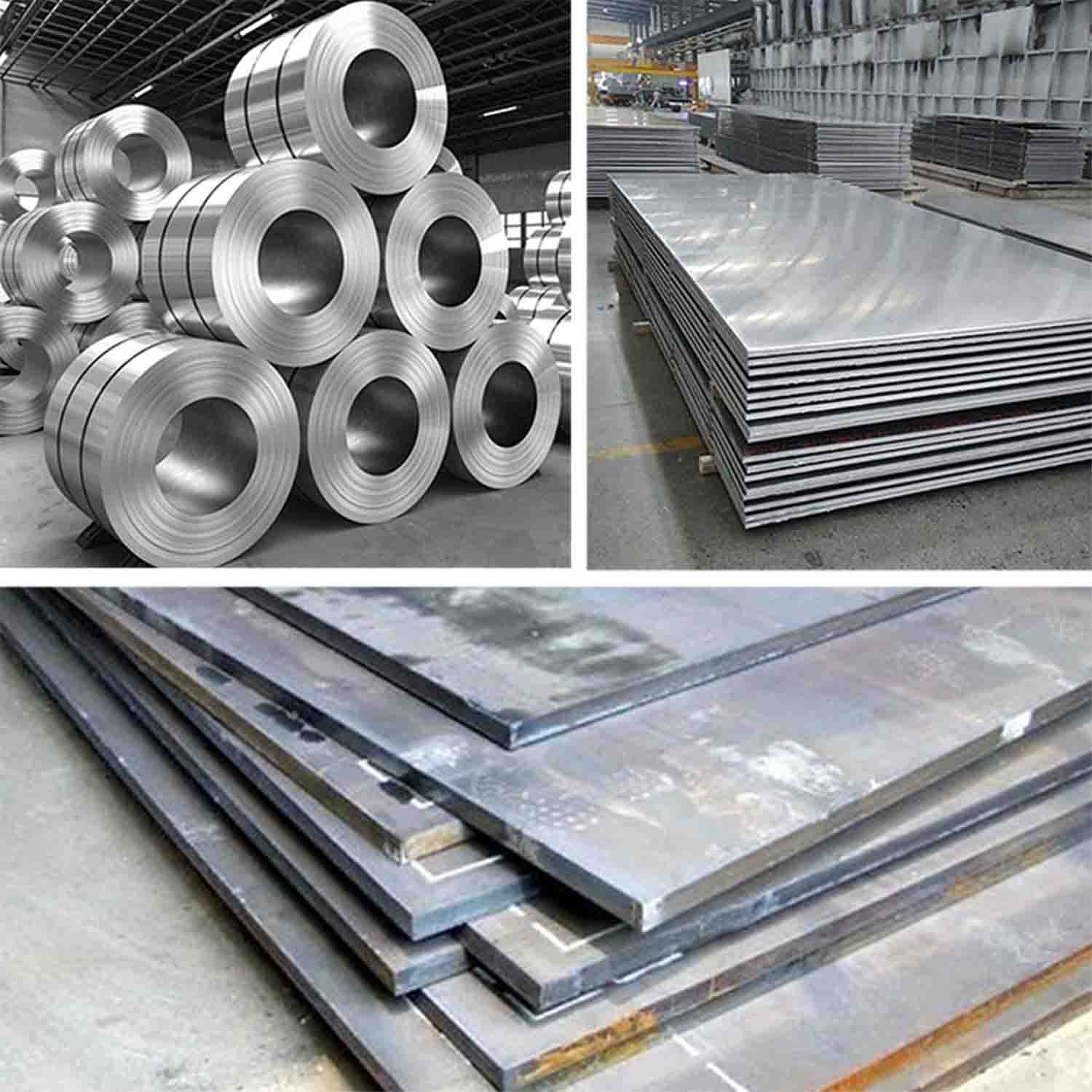

Stainless Steel 32760/50 Sheet Plate Coils are high-performance super duplex stainless steel products widely used in industries requiring exceptional corrosion resistance, strength, and durability. These alloys, known for their superior toughness and pitting resistance, are ideal for applications in harsh environments such as marine, chemical processing, oil & gas, and desalination plants. Due to their duplex microstructure, SS 32760/50 sheets, plates, and coils offer a unique balance of ferritic and austenitic properties, making them a preferred choice for demanding engineering projects.

Overview of Stainless Steel 32760/50

UNS S32760 and UNS S32750 stainless steels are part of the super duplex stainless steel family, providing excellent resistance to chloride-induced stress corrosion cracking, crevice corrosion, and general corrosion. Their high strength-to-weight ratio and durability make them suitable for structural applications where both performance and longevity matter. These grades are commonly supplied as hot rolled and cold rolled sheets, plates, and coils, available in a wide range of sizes, thicknesses, and finishes to meet diverse industrial requirements.

Key Features of SS 32760/50 Sheet, Plate & Coil

- Exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking

- Superior strength compared to conventional stainless steels

- Good weldability and workability

- Suitable for use in highly aggressive and corrosive environments

- Available in multiple forms: sheets, plates, coils, strips, and cut-to-size blanks

Available Finishes

To meet aesthetic, functional, and performance requirements, Stainless Steel 32760/50 Sheet Plate Coils are offered in various surface finishes, such as:

- 2B Finish – Smooth, reflective, and easy to clean; ideal for general fabrication

- BA (Bright Annealed) Finish – Highly reflective and suitable for architectural or decorative applications

- No.1 Finish – Hot rolled, annealed, and pickled; best for industrial and structural uses

- No.4 Finish – Brushed, satin-like appearance for decorative and architectural purposes

- 8K Mirror Finish – Ultra-smooth and reflective, used in high-end decorative applications

- Matte & Custom Finishes – For specialized industrial applications

Applications of Stainless Steel 32760/50 Sheet, Plate & Coil

The unique properties of these super duplex stainless steels make them indispensable in:

- Oil & Gas Industry – Offshore platforms, subsea pipelines, and processing equipment

- Marine Industry – Shipbuilding, desalination plants, and seawater handling systems

- Chemical Processing Plants – Storage tanks, pressure vessels, and chemical reactors

- Pulp & Paper Industry – Digesters, bleach washers, and evaporators

- Power Generation – Heat exchangers, condensers, and turbine components

- Pharmaceutical and Food Processing – Hygienic surfaces resistant to contamination

- Construction & Infrastructure – Structural frameworks, bridges, and architectural features

Advantages of Using Stainless Steel 32760/50 Sheet, Plate & Coil

- Superior corrosion resistance in chloride-rich and acidic environments

- Long service life with minimal maintenance costs

- Excellent mechanical strength and impact toughness

- Wide range of sizes, finishes, and thicknesses to suit all project needs

- Cost-effectiveness over the product life cycle due to durability

- Compatibility with welding and forming techniques, allowing easy fabrication